+48 71 780 30 20 / info@camdivision.com

+48 71 780 30 20 / info@camdivision.com

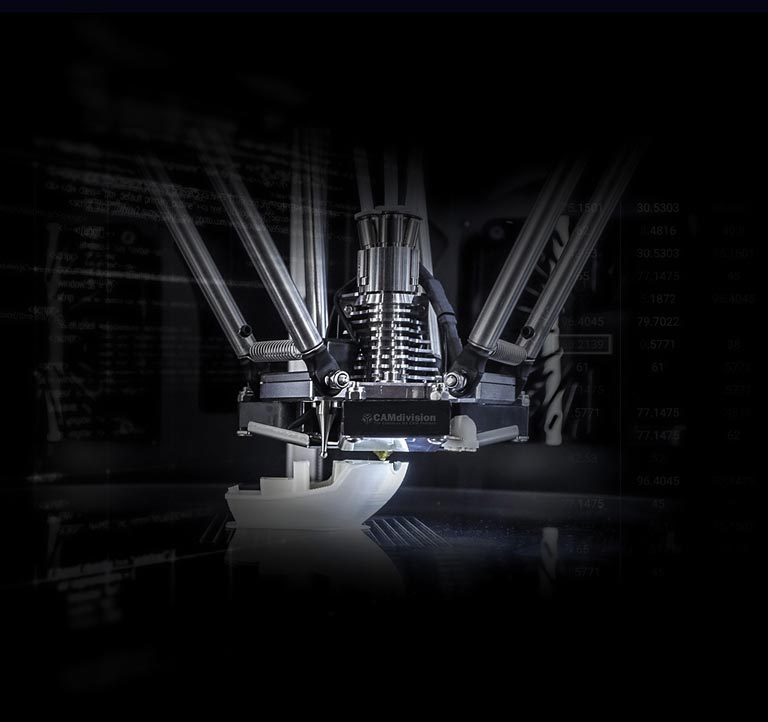

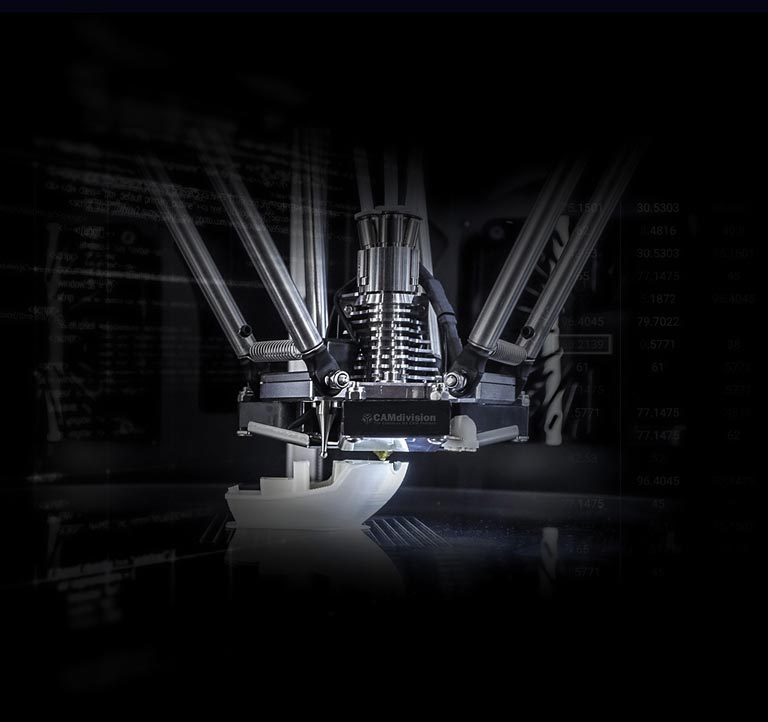

Additive Manufacturing is a change in the production method of products which, with the use of 3D printers and hybrid machines, enables the transfer of incremental manufacturing from the area of prototypes to the production level.

CAMdivision is the first company in Poland to implement solutions for 3D metal and plastic printing supported by NX CAD/CAM software packages. NX software provides a single, integrated system that is able to meet the unique challenges of designing, optimising and manufacturing components using incremental methods.

![]()

NX CAD/CAE/CAM is a comprehensive design, simulation and manufacturing platform that provides you with the ability to combine special modeling features with design and topology optimization capabilities to develop breakthrough designs using additive technologies.

Support for the full range of technologies

Preparation and 3D printing of a new class of parts is carried out using Additive Manufacturing technologies including Powder Bed Fusion and Jet Fusion (both supported by Materialise), Hybrid Additive and Fused Deposition Modelling as well as Nesting 3D and Lattice Structure (3D meshes).

Workflow to reshape conventionally designed parts

NX design and performance optimisation gives designers and engineers a wide range of options for developing next-generation products. Breakthrough technology allows designers to quickly create innovative and uniformly shaped parts that have improved performance and that meet specific industry requirements, while enabling them to be efficiently 3D printed.

Convergent Modelling Technology

From an engineer's point of view, this is an innovative technology that greatly simplifies work on geometry consisting of walls/stripes (STL), surfaces and solids. This innovative design method helps engineers to optimise part design for 3D printing and to speed up the whole process.

Scan-to-print

With Convergent Modeling technology, users can immediately start using scanned data to design products. The combination of convergent modelling with the ability to make parts using 3D printing directly from NX simplifies the incremental manufacturing process. The new process, which includes scanning, editing and printing, supports 3D manufacturing format 3D (3MF) and Microsoft's 3D printing features.

Topology optimisation

NX allows designers and engineers to create and optimise a whole new generation of products by ensuring that performance requirements are considered from the very beginning of the process. The resulting shapes are lightweight and optimally meet all performance requirements.

These groundbreaking designs can be easily modified in NX thanks to advanced functionalities such as Convergent Modelling and Synchronous Technology, which create a single and complete environment for the design of incrementally manufactured components.

Design principles for 3D printing

Verification of designs for 3D printing is an essential step in the process. NX offers verification tools to perform the necessary checks:

Determine the minimum wall thickness to ensure the feasibility of printing the part.

The overhang angle allows the identification of those regions of the part that require support.

Completely enclosed spaces can be identified in order to ensure effective treatment of these areas after printing.

The print volume function calculates whether the part is within the printer's volume limits.

These verification tools support data preparation and ensure the printability of designed parts.

Print preparation

NX performs the entire 3D printing process by providing solutions for a wide range of incremental technologies applied to both plastic and metal parts. Optimised product models from the design and simulation phase can be quickly prepared for 3D printing.

Setting up print operations

NX helps engineers to layout parts and define the necessary supports to prepare the setup for 3D printing. New NX solutions allow for quick loading of the execution setup and easy positioning of printed parts using advanced capabilities.

Part Layout – 2D and 3D Nesting

Optimised nesting of multiple parts can significantly increase the efficiency of additive manufacturing. Metal parts can be quickly positioned and arrayed using interactive assembly tools. The layout of parts can minimise the extent of necessary use of supports, thus enabling a reduction in the necessary finishing of printed parts.

Creating support structures

The creation of supports for metal parts created using powder melting methods is a necessary step, which, however, can be complicated and time-consuming. NX allows you to automatically generate support geometry (supported by Materialise technology) while maintaining association with the project model.

Full associativity ensures automatic updates of support structures in the event of successive technological changes in the project. The user has the freedom to make adjustments to the support geometry, for example using perforated walls to speed up printing and increase part quality.

Generating printer control code

3D printers require a specific set of parameters in order to effectively implement the incremental manufacturing process.

NX provides the ability to support a wide range of 3D printers for printing plastic and metal parts. By using predefined parameters, it is possible to create appropriate printing processes for the selected 3D printer, material and the printing strategy.

To verify the incremental manufacturing process, the current laser path can be reviewed "layer by layer" before sending it to the printer.

Powder bed 3D printing

Preparation and 3D printing of a new class of part is done using Additive Manufacturing technologies including Powder Bed Fusion and Jet Fusion (both supported by Materialise), Hybrid Additive and Fused Deposition Modeling, and Nesting 3D and Lattice Structure (3D meshes).

NX has specific software packages to support:

NX MACH 3 Additive Design with Convergent

Mach 3 Additive Design with Convergent includes all design capabilities of Mach 3 Product Design, as well as added functionality for designing parts that will use additive manufacturing processes. This includes advanced Convergent Modeling functions for working with polygon models as well as specific additive manufacturing functionality.

NX Additive Design with Convergent Sticky Add-on

The NX Additive Design with Convergent Sticky Add-on includes functionality for designing parts that are suitable for being produced using additive manufacturing methods

NX AM Fixed-Plane Basic

This includes powder bed systems and fixed-axis extrusion systems. It provides build tray setup, basic support geometry creation, and the build processor framework, which supports build processors for a wide variety of Additive Manufacturing equipment. This bundle includes solid modeling and drafting, feature modeling, basic freeform modeling, assembly modeling, and user defined features.

NX AM for Multi Jet Fusion

This is a manufacturing authoring application for Multi Jet Fusion Powder Bed Additive Manufacturing systems. It provides build tray setup, basic 3D nesting, and the build processor framework. This package provides a build processor for the HP Multi Jet Fusion system. This bundle includes solid modeling and drafting, feature modeling, basic freeform modeling, assembly modeling, and user defined features.

NX AM Fixed-Plane Advanced

This is a manufacturing authoring application for fixed plane Additive Manufacturing. This includes powder bed systems and fixed-axis extrusion systems. It provides build tray setup, advanced support geometry creation, 3D nesting, and the build processor framework, which supports build processors for a wide variety of Additive Manufacturing equipment. This bundle includes solid modeling and drafting, feature modeling, basic freeform modeling, assembly modeling, and user defined features.

The eBooks are electronic NX CAD books (in PDF format) aimed at individual NX users who want to improve their skills in using Synchronous Technology (ST), as well as at users of other CAD systems who want to learn about synchronous technology.

As far as technical details are concerned, you will receive links to download the individual files of the NX CAD book to the email address provided in the survey. However, we are not a non-profit organization, so we reserve the right to contact selected users of our free publications. The publications are intended exclusively for CAMdivision Sp. z o.o. customers or as an addition to free trial versions of NX.

NX Synchronous Technology

Synchronous Technology 3D

NX CAM Podstawy

Frezowanie 3-osiowe

NX ST & Realize Shape

Realize Shape & ST

Printed manuals are addressed to beginners and advanced users of NX CAD/CAM software. The publications are intended for CAMdivision Sp. z o.o. customers or as an addition to free trial versions of NX.

Book preview/order online

Our activity is not limited only to software implementations. We publish printed manuals and free eBooks, innovative on the Polish market. Additional sources of information about the software offered by us are information materials in the form of leaflets and video recordings of webinars organised by us. You will find detailed descriptions of products and configurations as well as descriptions of the latest software versions.

NX CAD/CAM trial versions are free trials of NX software, which includes selected NX CAD, NX CAM and NX CAE packages or specialised applications of the NX Mold/Progressive Design type (mould and die design).

Within the scope of the NX CAD/CAM package, we provide you with:

The offer is addressed to companies only.