+48 71 780 30 20 / info@camdivision.com

+48 71 780 30 20 / info@camdivision.com

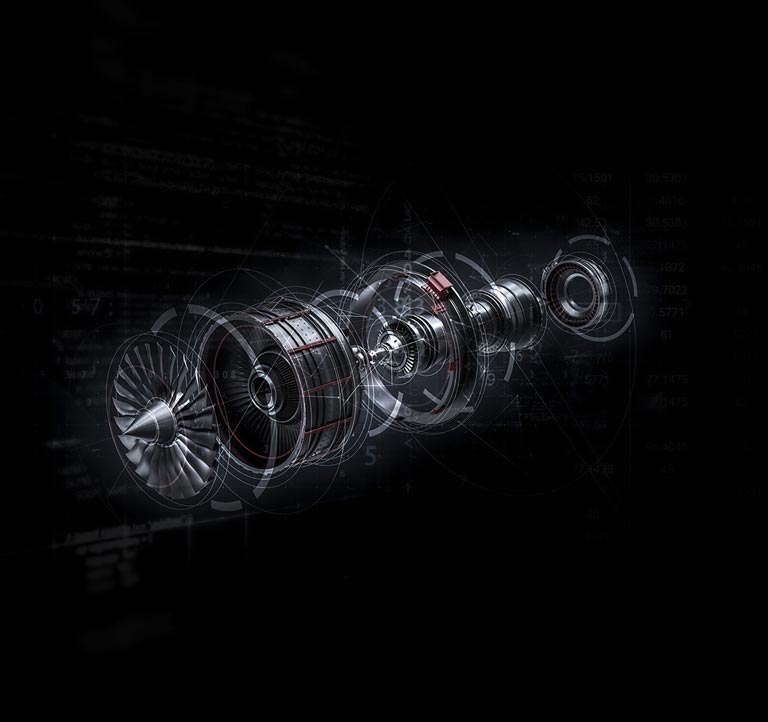

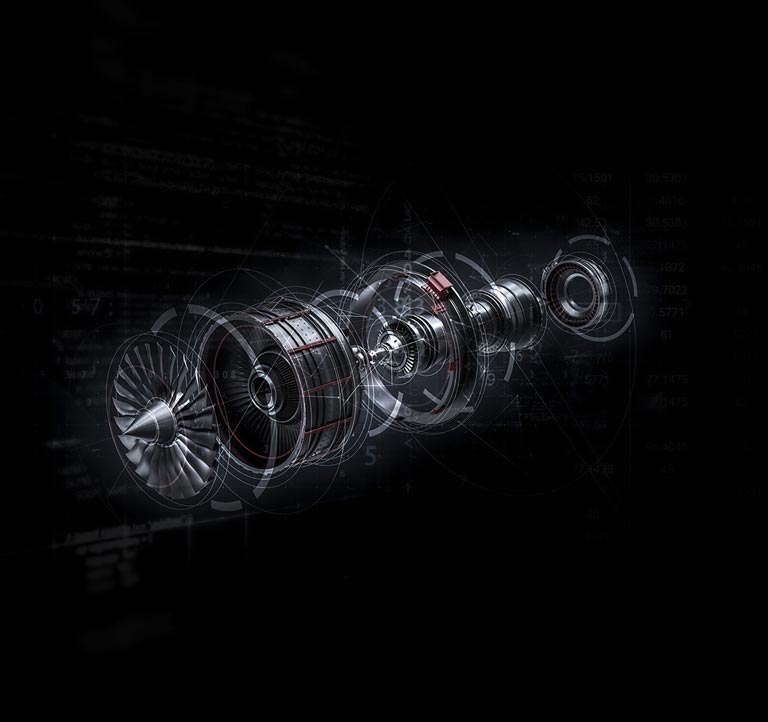

Modern composite materials offer significant opportunities for weight reduction, cost reduction, improved technical performance and reduced maintenance. However, the challenge of designing products using composites is that the part and the material from which it is made are developed simultaneously.

Components made of composites are used in many industrial fields Automotive, Aerospace & defence, Marine, Wind energy. CAMdivision is a member of Polish Cluster of Composite Technologies.

![]()

Composites are materials made by combining several materials. There is always a bonding phase, called a matrix or binder. The other materials in the composite are the reinforcement.

Material classification

Composite materials are classified in several ways. One of the better known classifications takes into account the division according to the type of reinforcement.

This division is as follows:

Composites reinforced with continuous fibres play a special role. Due to the mechanical properties of the fibres, materials with very high mechanical properties can be obtained while maintaining low material density. This makes it possible to construct structures that are very strong, stiff and lightweight at the same time.

Feasibility analysis

A very important aspect during the design process is to predict the feasibility of the designed geometry. Components with double curvature require special refinement. There are many problems associated with double curved geometries. From a practical point of view, it is necessary to foresee where the material must be cut in order to make it feasible in the mould and to avoid material kinks.

An additional difficulty from a strength point of view is the effect of fibre skew on the bi-directional curvature. Cross grain in the material changes the stiffness and strength in the laminate. According to the Classical Theory of Laminates, the skewing of fibres by even a small angle causes a significant decrease in stiffness...

FIBERSIM to support CAD/CAE/CAM design work

FIBERSIM software can help to analyse feasibility and support the whole process of design, strength analysis and manufacturing.

NX is a complete CAD/CAM/CAE solution from SIEMENS Digital Industries Software that also enables you to work efficiently on composite products with the specialised FIBERSIM module.

Designing, analysing and producing a composite is complex, specialised work that is best done when engineers have the tools to take into account a variety of parameters such as material type, fibre orientation, layer order, balance, symmetry, dropout, joints and folds. For this non-geometric information to be useful in the design process, it must form or relate to a specific geometry so that it can be viewed and modified simultaneously. This is what FIBERSIM is designed to do.

Design

FIBERSIM facilitates the processing of composite design data to produce a complete 3D product definition. The specification, requirements and purpose of the composite are associated with the geometry in a 3D CAD model. The program offers tools to automate repetitive design activities, such as material requirements and layer geometry.

In addition, the program automates different levels of visual and data presentation to optimally match the current design task, and produces a range of resulting data such as: design documentation, model-based format definitions and company reports.

Analysis

FIBERSIM facilitates composite product optimisation by enabling two-way communication between departments. Analysts understand that in order to get the most out of a composite, they need to determine the fibre orientation that provides the best structural properties – but they are constrained in doing so by material and manufacturing parameters. The software enables analysts to communicate desired fibre orientations to designers and manufacturing technicians.

Manufacturing

FIBERSIM facilitates the creation, management and definition of manufacturing by using design data and generating an associative manufacturing model. The software offers tools to automate the design for production, such as splicing, folding and layer edge adjustments for automatic deposition based on simulation of the production process, equipment and material parameters. FIBERSIM ensures high quality composite products by automating the creation of documentation and production data for moulding, slitting, fiber layout and inspection.

Fibersim works as a nested module in the NX CAD interface (also CATIA and Pro/Engineer).

FIBERSIM Pro

Enables a manual (Ply-based) method of layer design, but at the same time allows for design automation called Multi-Ply. Multi-Ply design is an easy-to-learn layer design method that automates detailed design tasks using special pre-specifications, greatly reducing the time to final result when making subsequent design changes.

FIBERSIM Elite

Extends the capabilities of FIBERSIM Pro and takes advantage of the key benefits of many different composite design methodologies - including structural, mesh-based, zone-based, volume-fill and layer-based - enabling efficient engineering of a wide range of products such as large and complex aerospace structures, automotive support structures, as well as jet engine blades.

Flat Pattern Export

The Flat Pattern Export license allows you to export flat blanks along with starting points, directional curves, markers and text annotations to automatic, or manual cutting machines from a variety of manufacturers. Supported brands include: Cutting Edge, GFM NS2, Magestic TruNEST, Optimation. Plataine TPO and JETCAM Expert.

Simcenter Structures

The Simcenter Structures licence allows you to use calculation tools that make use of the finite element method. It allows for linear, non-linear, modal, buckling, heat flow and spot weld analyses for both isotropic and anisotropic materials, such as fibre composites.

The eBooks are electronic NX CAD books (in PDF format) aimed at individual NX users who want to improve their skills in using Synchronous Technology (ST), as well as at users of other CAD systems who want to learn about synchronous technology.

As far as technical details are concerned, you will receive links to download the individual files of the NX CAD book to the email address provided in the survey. However, we are not a non-profit organization, so we reserve the right to contact selected users of our free publications. The publications are intended exclusively for CAMdivision Sp. z o.o. customers or as an addition to free trial versions of NX.

NX Synchronous Technology

Synchronous Technology 3D

NX CAM Podstawy

Frezowanie 3-osiowe

NX ST & Realize Shape

Realize Shape & ST

Printed manuals are addressed to beginners and advanced users of NX CAD/CAM software. The publications are intended for CAMdivision Sp. z o.o. customers or as an addition to free trial versions of NX.

Book preview/order online

Our activity is not limited only to software implementations. We publish printed manuals and free eBooks, innovative on the Polish market. Additional sources of information about the software offered by us are information materials in the form of leaflets and video recordings of webinars organised by us. You will find detailed descriptions of products and configurations as well as descriptions of the latest software versions.

NX CAD/CAM trial versions are free trials of NX software, which includes selected NX CAD, NX CAM and NX CAE packages or specialised applications of the NX Mold/Progressive Design type (mould and die design).

Within the scope of the NX CAD/CAM package, we provide you with:

The offer is addressed to companies only.